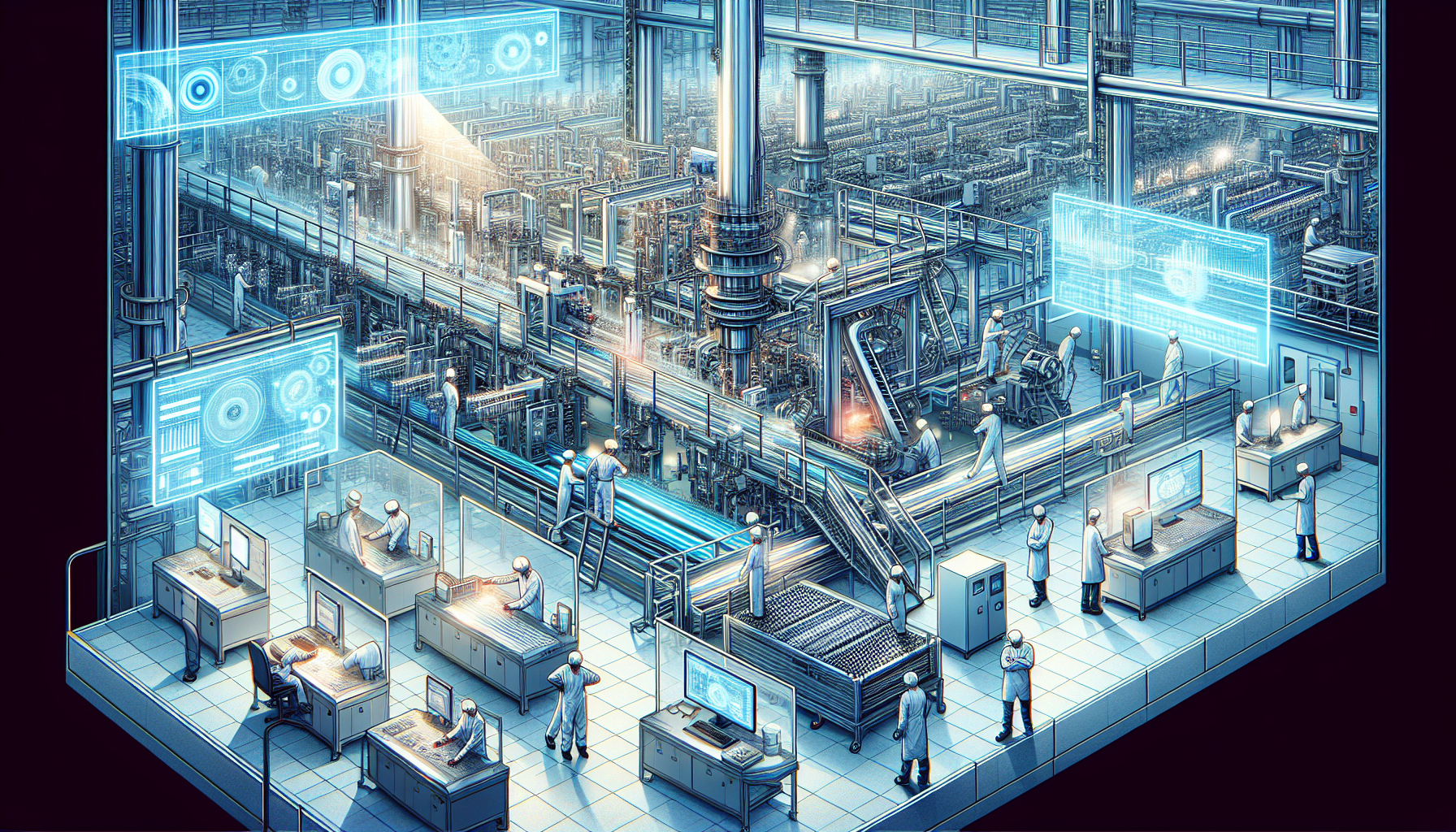

Oracle Manufacturing Execution System (MES) transforms manufacturing procedures and drives better enterprise collaboration with precise, agile, scalable features and integrations. As a key factor in maintaining real-time production oversight and navigating complex ERP integration initiatives, Oracle’s intuitive MES solution addresses both discrete and process manufacturing complexities.

Read on to learn how its essential components and capabilities deliver efficiency and quality control throughout your manufacturing journey and where our team of senior-level Oracle consultants can come in to help you maximize the technology you already own.

Key Takeaways

- Oracle MES is a comprehensive manufacturing execution system that enhances control over core manufacturing processes, integrates with ERP systems for quality management, and offers specialized solutions for both discrete and process manufacturing industries.

- Key components of Oracle MES include MES Workstation and MES Supervisor Workbench, which enable a single interface for shop floor operations and managerial oversight. These components can be personalized, thus improving efficiency, user experience, and decision-making.

- Oracle MES implementation requires careful planning, preparation, and ongoing training and support. It involves setting clear objectives, ensuring proper system and process integration, and providing necessary training for employees for successful adoption.

Understanding Oracle MES

As a robust manufacturing execution system (MES) that offers a comprehensive overview of production line activities in real-time, Oracle MES serves as the central command center for managing and monitoring manufacturing processes. The system’s unique features, such as the Auto Associate Serial Numbers parameter, enable precision in production processes, contributing to increased productivity and profitability across many industries, including pharmaceuticals, aerospace, and biotechnology. With manufacturing execution systems like Oracle MES, businesses can optimize their manufacturing processes and drive better business outcomes

Beyond simply managing operations, Oracle MES is committed to quality. It integrates seamlessly with Enterprise Resource Planning (ERP) systems, enhancing quality control and reducing inventory costs. Seamless ERP integration provides a comprehensive overview of manufacturing processes, bridging the gap between shop floor activities and overarching business goals.

Oracle’s MES software is not a one-size-fits-all solution. Recognizing the diversity of manufacturing needs across industries, Oracle MES offers specialized functionalities for discrete and process manufacturing. Whether managing serialized manufacturing or maintaining compliance with industry-specific regulations, Oracle MES is well-equipped to handle the complexities of both types of manufacturing.

Discrete Manufacturing

Oracle MES stands out in discrete manufacturing with its comprehensive suite of tools and functions, supporting various job operation actions, such as moving assemblies, completing operations, and managing exceptional cases like rejects or scraps. This level of control and oversight enhances the efficiency of the production process.

The system offers detailed resource transactions, job move transactions, and serialized job information as part of its job transactions business process. This includes associated numbers, descriptions, operator details, steps, and quantities. Such granular data allows for better manufacturing management and control, fostering increased efficiency and productivity across the board.

The dispatch list for discrete job operations in Oracle MES includes vital information such as:

- Scheduled times

- Assembly name

- Customer details

- Job readiness

- Components and resource availability

With configurable filtering criteria and labor reporting options, the dispatch list provides a practical overview of assemblies, job statuses, and scheduled quantities, contributing to the smooth flow of manufacturing processes.

Process Manufacturing

Shifting gears to process manufacturing, Oracle MES enhances environments by enabling electronic batch record keeping. Its Master Batch Record (MBR) serves as a documented set of manufacturing instructions, ensuring consistency and compliance across the production process. The Control Batch Record (CBR) records all events throughout a production batch’s life cycle, further enhancing transparency and control over the end-to-end manufacturing processes.

In compliance with FDA regulations, the MBR must include detailed information about the manufacturing process, ensuring product quality and consistency. Oracle MES goes a step further by offering the ability to create master, site, and general recipes. This flexibility provides specificity for process manufacturing needs, accommodating the unique requirements of organizations in the pharmaceutical, chemical, and food and beverage industries.

Key Components of Oracle MES

Under the hood of Oracle MES are two key components contributing to the system’s functionality: the MES Workstation and the MES Supervisor Workbench. The MES Workstation streamlines shop floor operations by offering a unified interface for operators, eliminating the need to switch between multiple transaction windows. This increases efficiency and simplifies the user experience.

On the other hand, the MES Supervisor Workbench serves as a managerial interface. It hosts a range of supervisory functions built into a single workbench, enabling a holistic view of and control over manufacturing operations.

Crucially, both components can be personalized. Users can tailor application pages in Oracle MES to suit their needs without altering the underlying base product code. This customization enhances the user experience, making the system more intuitive and user-friendly.

MES Workstation

The MES Workstation is designed with shop floor operators in mind. It offers the following benefits:

- Provides a single interface to perform multiple functions

- Eliminates the need to navigate through various transaction windows

- Boosts efficiency and productivity

Customizability is a key feature of the MES Workstation. Its interface can be tailored to consolidate views of jobs, requirements, and instructions, making it easier for operators to carry out critical tasks. Dispatch lists, a primary feature at the MES Workstation, present all job operations in the queue with customizable viewing. This enhances job access and overview for operators, ultimately improving the efficiency of the manufacturing process.

Notably, the MES Workstation also captures labor reporting data to track actual work. This includes recording direct labor time through intuitive Clock In and Clock Out mechanisms. Document printing features enable the printing of essential labels and job travelers required for the manufacturing process, further enhancing the functionality of the MES Workstation.

MES Supervisor Workbench

The MES Supervisor Workbench is designed to provide a comprehensive overview of manufacturing processes. It includes features such as an exceptions summary view, enabling detailed capabilities for managing exceptions within manufacturing processes. This empowers supervisors to manage and respond to material or labor shortages effectively.

The ability to evaluate the impact of exceptions on manufacturing processes is a crucial feature of the MES Supervisor Workbench. By understanding the implications of these exceptions, supervisors can determine appropriate resolution strategies, optimizing the production process.

The MES Supervisor Workbench also equips supervisors with a comprehensive view of shop floor activities and the capability to expedite jobs. This is particularly useful in addressing urgent manufacturing needs and optimizing production flow.

Enhancing Quality Control with Oracle MES

Quality control is a core focus of Oracle MES. The system captures nonconformance, the deviation from approved procedures, or the differences between observed conditions and acceptance criteria. This is critical for maintaining consistent quality management.

Oracle MES ensures that all procedures are up-to-date and consistent across the organization. By ensuring the use of current versions of standard operating procedures (SOPs), the system reduces the risk of nonstandard manufacturing practices and enhances overall quality control.

Electronic records play a vital role in Oracle MES’s quality control capabilities, providing an auditable trail of quality events and associated sign-offs, including the identity of the person signing, the date, time, and the reason for signing. This supports the traceability of products and ensures companies maintain compliance with industry regulations and standards.

Integrated Quality Management

Oracle MES integrates seamlessly with Oracle Quality to improve quality control and shop floor transaction reporting. This allows organizations to better track nonconformances and define quality instructions, ensuring that products meet the desired standards.

Labor skills validation is a feature in Oracle MES that confirms if employees working on specific job operations are qualified. This aids in compliance with quality standards such as ISO 9000, ensuring that only capable employees are tasked with crucial manufacturing processes. The job traveler feature assists in tracking the progress of these operations.

Standard Operating Procedures (SOPs) are critical to implementing Oracle MES. Ensuring that all procedures are up-to-date and consistent across the organization minimizes the chances of nonstandard practices and enhances overall quality control.

Electronic Records and Signatures

Oracle MES supports the US FDA’s 21 CFR Part 11 regulation for electronic records. This ensures compliance by capturing electronic records, production monitoring activities, and providing data traceability. The e-records and e-signatures (ERES) framework in Oracle MES is implemented using Oracle Workflow business events and Oracle XML Gateway, ensuring reliable record keeping.

The system supports several electronic signature types, verifying completed tasks on the shop floor using electronic signatures and enabling a paperless signing process. Oracle MES interacts with Oracle XML Publisher to print reports and electronic records in a human-readable format, aiding in their review and confirmation.

Incorporating electronic records and signatures into the manufacturing process offers several benefits:

- Ensures compliance with regulatory standards

- Contributes to a more efficient and streamlined manufacturing operation

- Eliminates the need for manual record-keeping and signature validation

- Allows manufacturers to focus more on their core manufacturing processes

Leveraging Real-Time Data for Informed Decision-Making

In today’s fast-paced manufacturing environment, real-time data is king. Oracle MES provides visibility into production processes with real-time data dashboards, shop floor monitoring, and production tracking. This supports rapid issue identification and resolution, enabling manufacturers to respond quickly to changes and optimize their operations.

Data-driven decisions are the cornerstone of modern manufacturing. Oracle MES enhances this by integrating predictive analytics tools, real-time reports, and performance dashboards into its system. This allows manufacturers to make informed decisions based on accurate, real-time data, enhancing efficiency and productivity.

The key benefits of Oracle MES for enterprise manufacturers include:

- Vital real-time production monitoring

- Electronic work instructions

- Production scheduling

- Improved operational efficiency

- Swift, informed decision-making

- Built-in support for mixed-mode manufacturing execution

Data Collection and Analysis

Oracle MES integrates with automated systems for accurate, real-time data collection. It utilizes advanced technologies like Internet of Things (IoT) and Machine Learning to optimize performance and maintenance management. By leveraging IoT data streams, Oracle MES employs predictive maintenance. This analyzes various data sources such as IoT, SCADA systems, and machine-to-machine communications to anticipate asset failure and calculate reliable equipment lifespans, optimizing costs and minimizing unplanned downtime.

Oracle MES also facilitates tracking production efficiency and productivity of manufacturing processes through Key Performance Indicators (KPIs). It supports accurate tracking of resource consumption through detailed reporting of hours worked on tasks, which helps in monitoring labor and machine usage.

Integrating with ERP Systems

Integration of Oracle MES with Oracle ERP and SCM systems creates a unified platform that aids in informed decision-making for managing manufacturing processes. This seamless integration facilitates data flow and manufacturing operations management, ensuring that every aspect of the manufacturing process is interconnected and optimized.

Oracle MES can also be deployed in a distributed mode, allowing 24-hour manufacturing operations to function independently if necessary. This flexibility provides control over manufacturing processes across various plants, without the immediate need to upgrade the central ERP system.

When integrated with Oracle E-Business Suite, MES for Process Manufacturing offers the following benefits:

- Streamlines operations

- Reduces data replication

- Minimizes errors

- Cuts costs

- Meets regulatory requirements

- Increases overall process efficiency

Adapting to Industry Trends and Technologies

Oracle MES is not a static system, offering real-time solutions that evolve with industry trends and align with the shift towards service-oriented, modular, and connected systems. This adaptability ensures that Oracle MES remains relevant and effective in the ever-changing manufacturing landscape.

Oracle MES offers the following benefits:

- Aligns with the industry trend of customized production, enabling mass personalization of products while maintaining speed and affordability

- Offers flexibility in deployment, with the ability to function independently of ERP in a distributed mode

- Facilitates event-driven management and control for continuous, plant-level manufacturing operations across multiple facilities

The system’s adaptability extends to its embrace of:

- Cloud connectivity

- IoT devices

- AI

- Machine learning

Embracing Cloud Connectivity

Manufacturers are increasingly adopting cloud MES solutions, which offer:

- Scalability

- Smaller upfront investments

- Fast deployment

- Remote accessibility

Cloud MES is facilitating the integration of AI tools within manufacturing processes. This provides predictive quality solutions and production operations, helping manufacturers anticipate and address issues before they become significant problems.

Cloud connectivity is the backbone of smart factories, enabling autonomous interactions between advanced manufacturing systems, devices, products, and equipment. By embracing cloud connectivity, Oracle MES is positioning itself as a leader in the move toward smart, connected manufacturing.

Harnessing the Power of IoT Devices, AI, and Machine Learning

Oracle MES’s integration with Oracle Analytics Cloud, Oracle Machine Learning, and OCI Data Science empowers manufacturers with advanced analytics, data science, and AI-driven insights. This is particularly useful for maintenance optimization, where predictive analytics anticipate asset failure and calculate reliable equipment lifespans.

The system provides tools for monitoring product specifications and controlling quality parameters. This helps reduce defects and ensure adherence to industry standards, contributing to improved quality control and consistent product quality.

MES systems, including Oracle MES, are increasingly incorporating digital twin technologies. By using cloud storage and computing capabilities, Oracle MES can enhance process optimization and enable detailed scenario analysis.

Implementing Oracle MES: Best Practices and Tips

Implementing Oracle MES is not simply a matter of installing new software. It involves careful planning, preparation, training, and support. Defining specific goals for Oracle MES implementation helps ensure the system aligns with the organization’s overall operational strategy. Conducting a thorough assessment of current processes and systems before implementation can also prevent integration challenges and align MES with current business objectives.

Customizing Oracle MES to match an organization’s unique workflows and processes can significantly enhance user adoption and system effectiveness. Successful integration of MES with existing ERP systems and machine automation is crucial for seamless data flow and manufacturing operations management. Moreover, setting up real-time data capture and reporting tools in the MES provides clear visibility into manufacturing activities, supporting quick decision-making and process optimization.

Training for employees is essential at the initial stages and as an ongoing effort to keep up with system updates and process refinements. Establishing a support framework that includes technical assistance, system monitoring, and user feedback collection contributes to the continuous improvement of MES deployment.

Planning and Preparation

A successful Oracle MES implementation begins with clear objectives and goals. These provide a roadmap for the project and define what the organization hopes to achieve with the system.

Creating a comprehensive timeline is essential to ensure that all tasks related to the implementation of Oracle MES are completed on schedule. This helps to keep the project on track and ensures that all necessary steps are taken promptly.

A thorough review of current systems and infrastructure is also critical. This helps determine the resources needed for Oracle MES implementation, ensuring the system fits seamlessly into the existing technological landscape. Allocating a well-defined budget for the Oracle MES project is another critical step that requires careful planning and execution to cover all necessary expenses.

Training and Support

Effective training is critical to the successful usage of Oracle MES. Employees must be equipped with the necessary qualifications to use the system competently. Proper training ensures that employees understand how to use the system effectively, reducing the risk of errors and increasing efficiency.

Ongoing support is also essential in ensuring employees comply with industry standards while using Oracle MES. Regular updates and technical assistance can help employees keep up with changes and refine their system use over time.

Oracle MES includes a labor skills validation process that helps in both initial training and ongoing support. This verifies employee qualifications for specific job operations, ensuring that only capable employees are tasked with crucial manufacturing procedures.

Wrapping Things Up

With its robust capabilities and adaptability to industry trends and technologies, Oracle MES is well-equipped to streamline manufacturing processes, enhance quality control, and provide real-time insights into production activities. Organizations can optimize manufacturing procedures, improve productivity, and increase profitability by implementing Oracle MES following the best practices and tips discussed in this blog post.

But without the right resources and personnel to implement a new Oracle MES software or optimize an existing system, your technical investment could all be for naught…

How Can We Help?

From outlining implementation plans for new Oracle applications to navigating complex integrations between Oracle and non-Oracle systems, managing data migrations across the Oracle landscape, or maintaining effective communication between project teams, Surety Systems can help.

Our senior-level Oracle consultants have the knowledge, skills, and experience to understand your critical project needs, execute the game plan, and prepare your internal teams for continued success long after we’ve rolled off the project.

For more information about our Oracle consulting services or to get started on a project with our expert consultants, contact us today.

Frequently Asked Questions

What is Oracle MES?

Oracle Manufacturing Execution System (MES) is a comprehensive solution that helps manage and monitor manufacturing processses, improve quality control, and provide real-time insights into production activities.

How does Oracle MES support discrete and process manufacturing?

Oracle MES supports discrete and process manufacturing by offering specialized functionalities, supporting job operation actions, electronic batch record keeping, and ensuring consistency and compliance in manufacturing processes.

What are the critical components of Oracle MES?

The critical components of Oracle MES are the MES Workstation and the MES Supervisor Workbench, which provide a single interface for shop floor operators and a managerial interface with supervisory functions.

How does Oracle MES enhance quality control?

Oracle MES enhances quality control by integrating quality management, using electronic records and signatures, and seamlessly integrating with Oracle Quality for enhanced control and reporting.

What are some best practices and tips for implementing Oracle MES?

When implementing Oracle MES, it is best to define specific goals, conduct a thorough assessment of current processes and systems, customize the system to match unique workflows, integrate MES with existing ERP systems and machine automation, set up real-time data capture and reporting tools, and provide training and support for employees.